https://www.usa.gov/copyrighted-government-workshttps://www.rawpixel.com/image/12306817

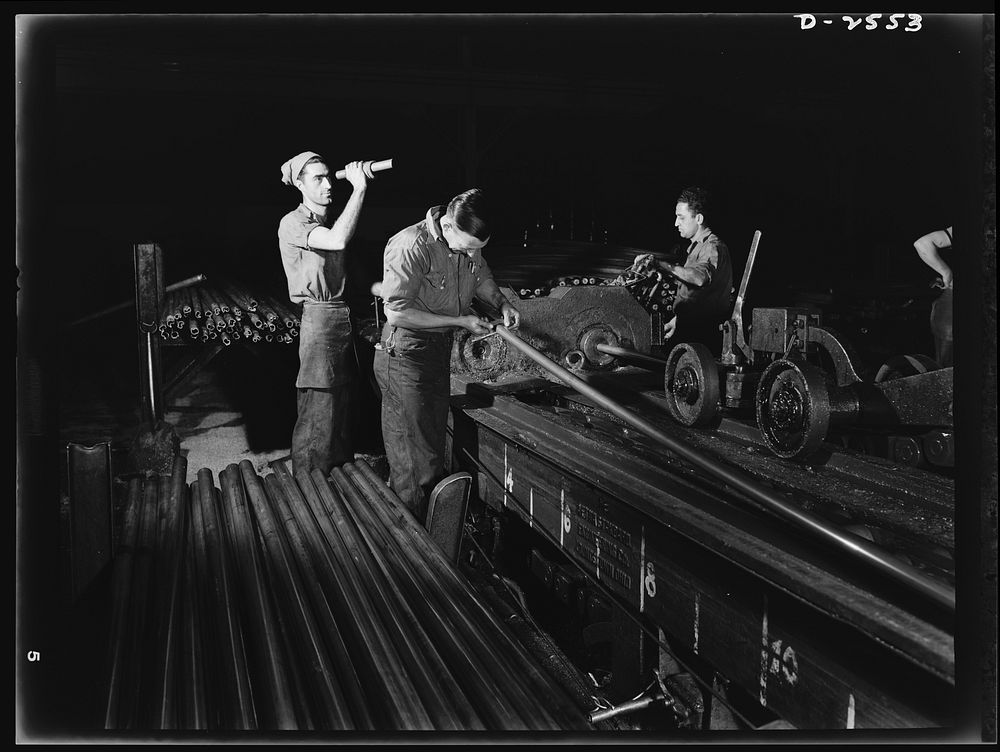

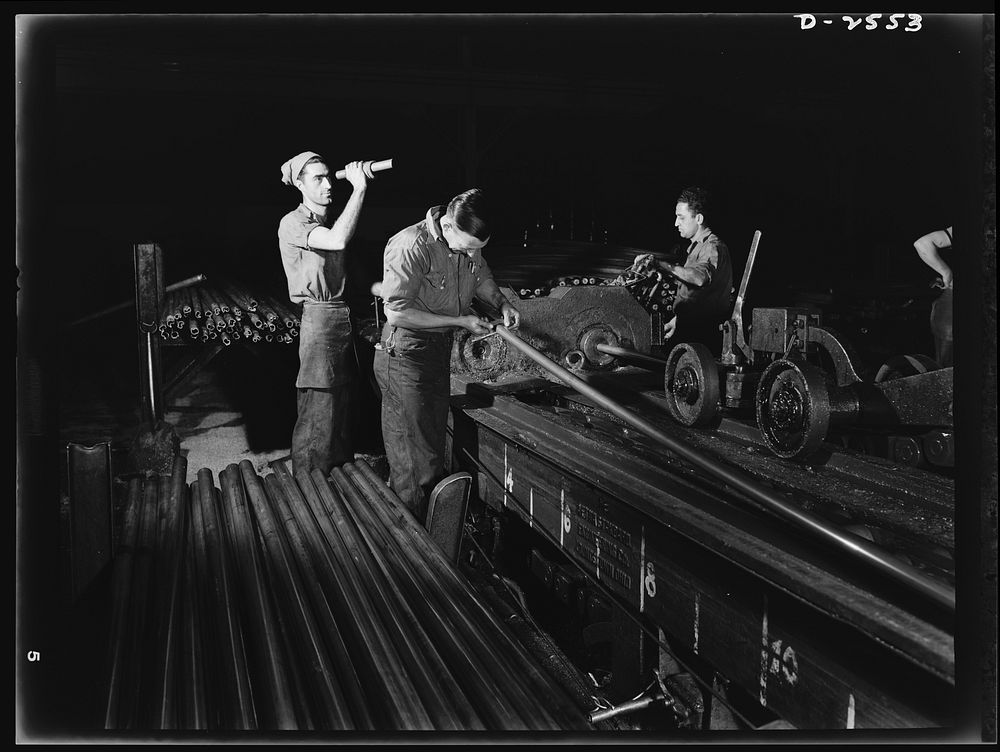

Conversion. Copper and brass processing. Drawing seamless copper tube. Rough cast tubes tapered at one end to fit through a die are gripped in the tongs of the electric motor-driven vehicle on the drawbench and pulled or "drawn" through the die to be reduced to the desired size. Tubes usually are redrawn many times; each successive "draw" reduces the diameter, and increases the length. Brass tubes need to be annealed or softened between each draw, but copper tubes can be drawn several times without intermediate annealing. The tapered nose of the tubes may be seen just behind the drawbench operator. Chase Copper and Brass Company, Euclid, Ohio. Sourced from the Library of Congress.

View public domain image source here

Public DomainFree CCO U.S. Government image for Personal and Business use